Non-JIT-adherent employees of your team might have a negative impact on your productivity, quality, and other factors. It is possible for the manufacturing process to be halted by supply chain issues. Kanban, which is the Japanese word for “sign,” is a just-in-time inventory control system developed by Toyota that allows employees to quickly signal when it’s time to order new shipments of parts. Short multiple-choice tests, you may evaluate your comprehension of Inventory Management.

Editorial Team

Through the careful implementation of your taxable incomeologies, manufacturers can reduce inventory levels, lower ongoing costs, increase product quality and achieve greater overall efficiency. However, even if a company does everything right, JIT manufacturing is not without risks. As the COVID-19 pandemic showed, JIT processes are highly susceptible to disruptions in the supply chain.

- The Just-in-Time (JIT) inventory management system is a method of keeping inventory levels as low as possible by receiving goods only as they are needed for production or sale.

- The raw materials are then received by the manufacturer, assembled, and sold to the customer.

- JIT inventory management requires a high degree of discipline and adherence to strict production schedules.

- We should point out that JIT inventory and JIT manufacturing are somewhat different.

Product

Erika Rasure is globally-recognized as a leading consumer economics subject matter expert, researcher, and educator. She is a financial therapist and transformational coach, with a special interest in helping women learn how to invest. In this article, you’ll learn everything you need to know about JIT manufacturing. Having standard procedures in place for every operation ensures that the outcomes are reliably predictable. That includes how long the procedure should take and what quality items it should produce. When a deviation from the norm is detected, measures can be taken to identify the cause of the inconsistency.

Drawbacks of JIT Inventory Management:

All three of these elements ensure an optimized and efficient process to turn raw materials into products for customers. Visit our guide to inventory management terms and acronyms to brush up your knowledge on production processes, customer demand, and inventory management efficiency. The just-in-time, or JIT, inventory system is a strategy in which orders of raw materials for manufacturing are aligned closely with production schedules. A just-in-time strategy eliminates overproduction, which happens when the supply of an item in the market exceeds the demand and leads to an accumulation of unsalable inventories. These unsalable products turn into inventory dead stock, which increases waste and consumes inventory space.

Although you need less cash on hand in JIT, you still need to have some in reserve in case of unexpected events. Results will always vary depending on the business and production context, but the JIT model is quite popular and well-received in most manufacturing environments. While the benefits of JIT are well-documented, the COVID-19 pandemic has revealed the method’s weaknesses. As trade was disrupted by lockdowns and travel bans, companies have found managing its supply chain to be incredibly difficult. In this article, we’ll review different examples of how companies—both large and small—are implementing a JIT inventory strategy.

Large companies should be able to cope with this (particularly as the JIT method frees up cash flow), but for smaller businesses, a sudden price hike can really affect your bottom line. Minimizing the amount of inventory on hand gives you more freedom in terms of cash flow, as you’ll have less working capital tied up in the various costs of purchasing, storing, and replenishing stock. You’ll also save on labor costs, as it takes fewer staff to manage a minimal inventory. Carrying smaller numbers of items at a time means there’s less chance of losses through accidental damage or spoilage of fresh goods (remember it’ll cost you to scrap them), or due to theft. It’s also much easier to identify any defective items when inventory levels are low, and you’ll have the agility to abandon products that are no longer selling well. That’s why JIT inventory is useful for small e-commerce businesses and major fashion retailers alike, as you can use demand forecasting to produce or procure the right amount of apparel or accessories.

If you’re not sure whether a JIT system is right for your business (or you don’t think you’re properly set up for it yet), there are a couple of things you can do to prep your company for the JIT method. Since you have to replenish stock as soon as you sell it, you don’t have the luxury of waiting around for the best price. So if your supplier charges extra for your order due to a recent natural disaster or national holiday, it’ll eat into your bottom line. Someone on our team will connect you with a financial professional in our network holding the correct designation and expertise. Our writing and editorial staff are a team of experts holding advanced financial designations and have written for most major financial media publications. Our work has been directly cited by organizations including Entrepreneur, Business Insider, Investopedia, Forbes, CNBC, and many others.

Instead of spending all your revenue from the past month on a massive replenishment order, you can allocate a small portion of your earnings for inventory. With JIT, you don’t have to worry about unwanted inventory in the event an order gets canceled or is not fulfilled for any other reason. This allows them to keep optimal levels of stock and eliminate excess inventory that would lead to waste.

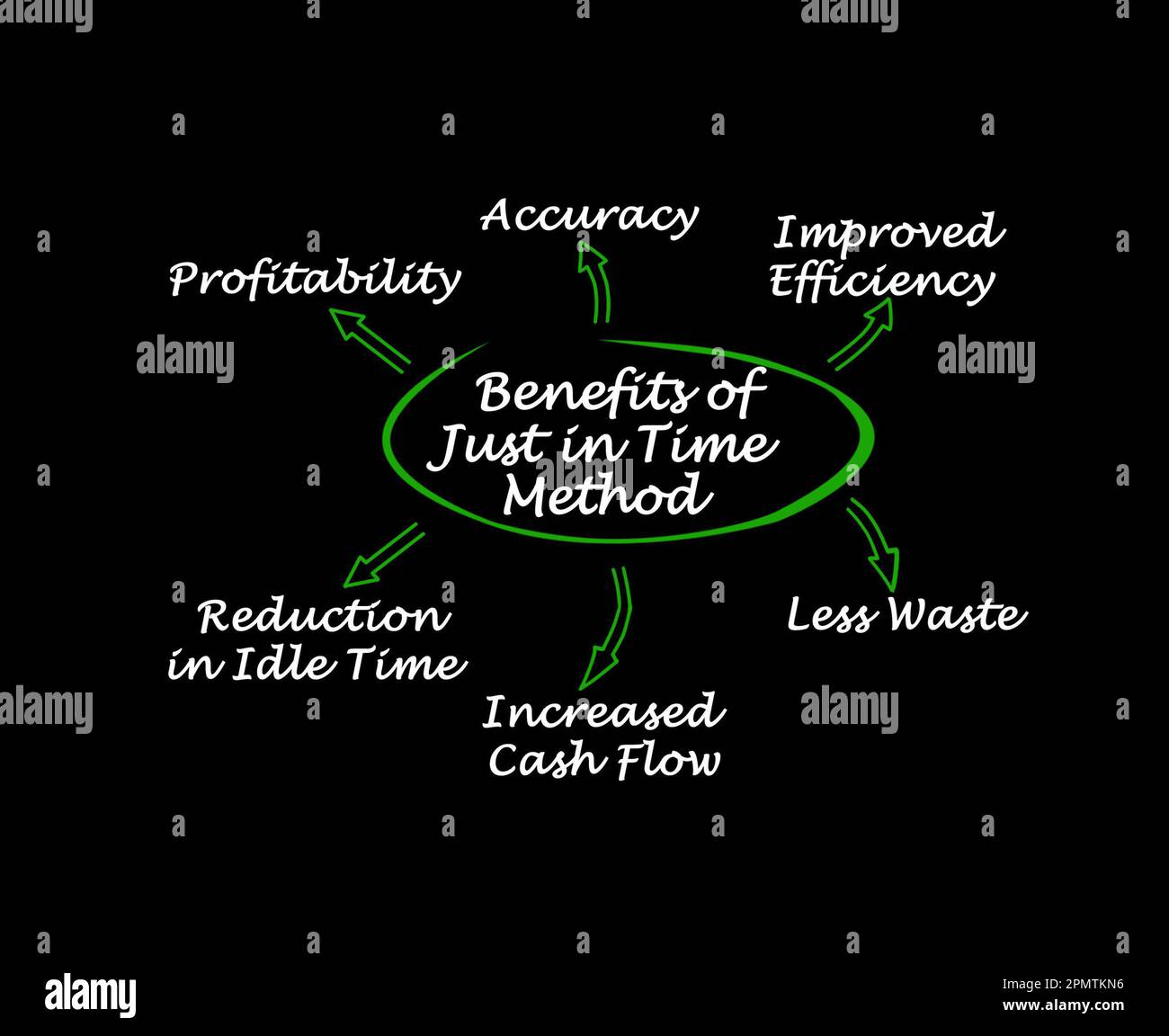

That would save a great deal of money, for it would give a very rapid turnover and thus decrease the amount of money tied up in materials. As a result, the manufacturer only orders the components necessary to construct the automobiles after an order has been received. Companies that are successful in using just-in-time methods minimize inventory, maximize efficiency, and increase profitability. JIT inventory management is a valuable production strategy that can help businesses stay competitive in today’s fast-paced and constantly evolving marketplace. JIT inventory management requires a high degree of discipline and adherence to strict production schedules. This can be challenging if employees are not fully trained on JIT principles and practices, or if there is resistance to change.